CRAC Coating Performance in Phosphatic Slurry Environment

In fertilizer production facilities, phosphatic slurry is one of the most corrosive process media, a mixture of phosphate rock and sulfuric acid that continuously attacks plant structures, tanks, and pipelines. Such environments make corrosion control a constant challenge for maintenance teams.

"Is your business ready to embrace sustainability in construction and repair? Looking for eco-friendly solutions that don't compromise on performance?"

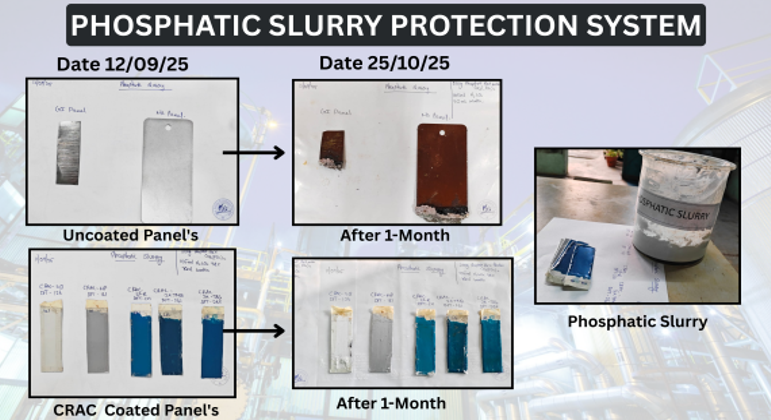

To evaluate the performance of CRAC (Chemical Resistant Anti-Corrosion) paint under these harsh conditions, a comparative test was conducted on Mild Steel (MS) and Galvanized Iron (GI) panels, both coated and uncoated.

Test Setup:

The phosphatic slurry was prepared using: - 200 g Phosphate Rock Powder (Ca₃(PO₄)₂) - 105 ml Sulfuric Acid (H₂SO₄) - 70 ml Water All samples were exposed under identical conditions for a fixed duration to simulate real-time plant exposure

Results:

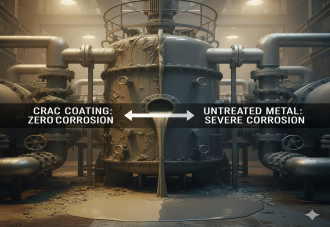

After the test duration, the difference was clearly visible. The uncoated MS and GI panels showed severe corrosion, heavy rusting, and thick deposits of phosphate salts. The GI panel developed a dark brown corrosion layer with white phosphate deposits, while the MS panel suffered deep pitting and complete surface deterioration. In sharp contrast, the CRAC-coated panel showed no visible damage its surface remained smooth, without any blistering, peeling, or color change. This proved that CRAC effectively resists aggressive chemical attacks, forming a non-reactive, protective barrier that isolates the metal from the corrosive slurry.

Conclusion:

This experiment clearly demonstrates that CRAC provides exceptional chemical resistance in highly acidic phosphate environments where conventional metals fail within hours or days. By forming a dense, chemically inert barrier, CRAC prevents acid and phosphate ions from reacting with metal surfaces ensuring long-term protection, reduced downtime, and extended equipment life.

For fertilizer and chemical plants, CRAC is not just a coating — it’s a long-term corrosion protection solution.