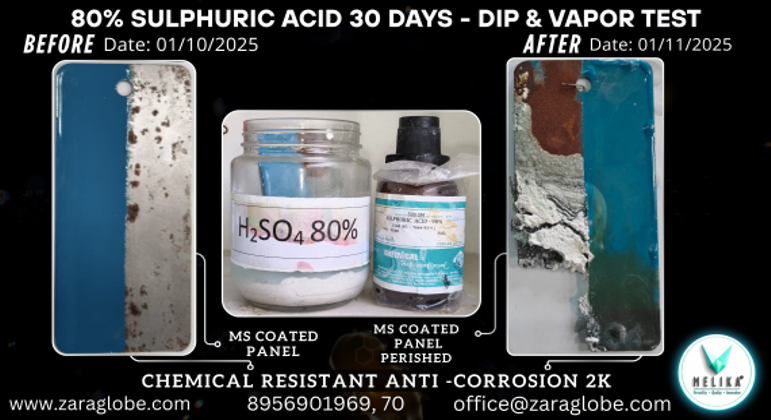

Advancing Structural Protection Against Sulphuric Acid

At Zara Globe Solutions Pvt. Ltd, we are proud to share a major breakthrough that our CRAC (Chemical Resistant Anti-Corrosion) paint can now successfully withstands Sulphuric Acid up to 80% concentration, and our team is continuously working to extend this capability up to 98% concentration soon.

"Is your business ready to embrace sustainability in construction and repair? Looking for eco-friendly solutions that don't compromise on performance?"

Why It Matters

Sulphuric Acid (H₂SO₄) is one of the most widely used industrial chemicals, especially in fertilizer, chemical, and metal processing plants.

However, its highly corrosive nature leads to:

- Damage to concrete and steel structures

- Leakages, safety risks, and costly downtime

- Frequent maintenance in acid storage and handling areas

How CRAC Protects

CRAC forms a durable, chemical-resistant barrier that prevents acid attack and extends the life of industrial structures.

- On concrete: Attacks silica, leading to erosion and deep surface damage.

- On steel: Dissolves protective oxide layers, causing rapid pitting and failure.

- On glass & ceramics: Instantly dissolves silica, leading to etching and cracking.

Corrosion Effects of Sulphuric Acid in Industrial Environments

Sulphuric Acid (H₂SO₄) is highly corrosive and widely used in fertilizer, chemical, and metal processing industries. Its contact with metal or concrete surfaces leads to rapid material degradation, structural damage, and costly maintenance. Both liquid and vapor phases of the acid can cause severe corrosion if not properly controlled or protected.

Major Corrosion Effects:

- Attacks carbon steel, iron, zinc, and copper forming sulphates and hydrogen gas, leading to pitting, rusting, and embrittlement.

- Reacts with calcium compounds, forming soluble salts that cause surface erosion, cracking, and loss of strength.

- Fumes condense on nearby structures, initiating hidden corrosion and coating failures.

- Continuous exposure in bunds, drains, and tank foundations results in concrete softening and reinforcement corrosion.

- Reduces load-bearing capacity, shortens equipment life, and increases the risk of leaks and safety hazards.

At Zara Globe Solutions, we remain committed to delivering innovative, high-performance protective coatings that safeguard industrial infrastructure and enhance operational reliability.